The function of image processing devices in fruit sorting is to automate the inspection and categorization of fruits based on various quality parameters. This involves several interconnected components and processes working together to ensure efficient and accurate sorting. Here's a detailed breakdown of how these devices function:

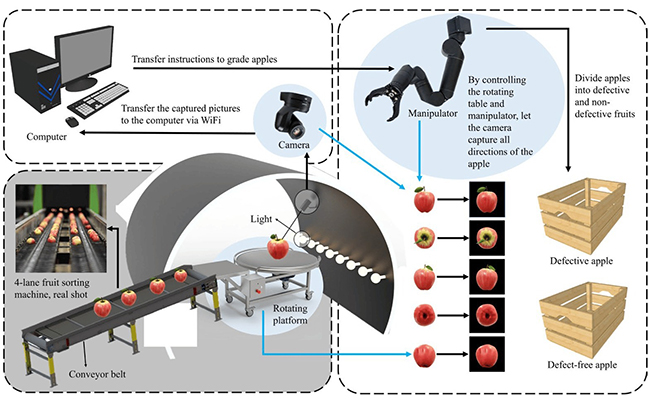

1. Image Acquisition

Cameras

- High-resolution cameras are positioned strategically along the conveyor belt

- Multiple cameras may be used to capture different angles of the fruit to get a complete view.

Lighting Systems

- Proper illumination is crucial for capturing clear images

- LED lighting, diffuse lighting, or structured lighting is used to eliminate shadows and reflections

2. Image Preprocessing

Noise Reduction

- Filters are applied to the images to remove any background noise or irrelevant details.

Normalization

- Adjusting the brightness and contrast of images to ensure uniformity across all captured images.

3. Feature Extraction

Size Measurement

- Algorithms measure the dimensions of the fruit to determine its size category

Shape Analysis

- The contour and overall shape are analyzed to detect any deformities or irregularities.

Color Analysis

- Color histograms and other techniques are used to analyze the fruit's color, indicating ripeness and detecting any discoloration.

Texture Analysis

- The surface texture is examined for defects like bruises, scars, or blemishes.

4. Classification

- TrainingThe system is trained with a dataset of images to learn how to classify different types of fruits and detect defects

- Real-Time ProcessingThe classification process is performed in real-time as fruits move along the conveyor belt.

- Machine Learning Algorithms Algorithms such as Support Vector Machines (SVM), Neural Networks, and Decision Trees classify the fruits based on the extracted features.

5. Sorting Mechanism

Mechanical Arms

- Robotic arms pick and place fruits into the appropriate bins based on the classification.

Air Jets

- Bursts of air are used to push the fruits into different bins

Conveyor Diverters

- Sections of the conveyor belt can move to divert fruits into specific bins.

6. Integration and Control

Central Control System

- A central control unit coordinates all components, from image acquisition to sorting.

- It ensures synchronization and efficient processing

User Interface

-

Operators can monitor the system, adjust settings, and review sorting performance through a user-friendly interface

Advantages

- Efficiency Capable of processing large volumes of fruits quickly and accurately.

- Consistency Ensures uniform quality by eliminating human error.

- Data Collection Provides valuable data for improving agricultural practices and predicting yields.

- Cost Savings Reduces labor costs and minimizes wastage by accurately sorting fruits.

Advantages

- Initial Setup Cost Capable of processing large volumes of fruits quickly and accurately.

- Maintenance Ensures uniform quality by eliminating human error.

- Complexity Provides valuable data for improving agricultural practices and predicting yields.

Future Trends

- Artificial Intelligence (AI) and Deep Learning Improved algorithms for accuracy and adaptability.

- Internet of Things (IoT) Integration Real-time monitoring and data analysis through IoT devices.

- Advanced Robotics More sophisticated robotic systems for efficient sorting mechanisms