Machine vision systems and laser control provide numerous benefits to button factories, significantly enhancing efficiency, quality, and productivity. Here’s how these technologies can help

1. Improved Quality Control

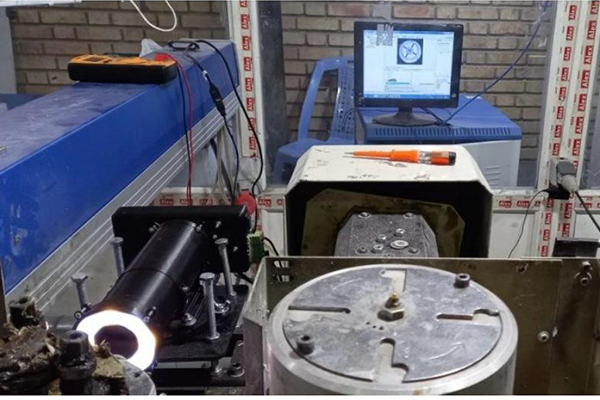

Machine Vision Systems

- Consistent Inspection Machine vision systems provide consistent and objective inspection of buttons, eliminating human error.

- Precision Measurement Accurate measurement of button dimensions ensures they meet specified tolerances, improving product uniformity.

- Defect Detection High-resolution cameras and advanced algorithms detect defects such as scratches, chips, or irregular shapes, ensuring only high-quality buttons proceed to the next stage

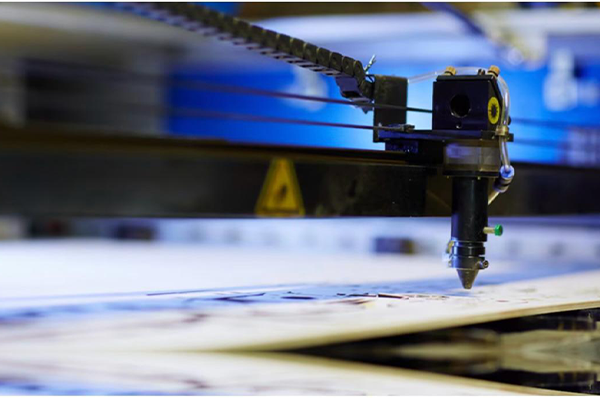

Laser Control

- Accurate Cutting and Engraving Laser control ensures precise cutting and engraving, maintaining high standards of design and functionality.

- Minimized Defects Non-contact laser processing reduces mechanical stress on buttons, minimizing defects and improving overall quality.

2. Increased Efficiency and Productivity

Machine Vision Systems

- High-Speed Processing Automated inspection can handle high volumes of buttons quickly, increasing throughput compared to manual inspection.

- Automated Sorting Machine vision systems can automatically sort buttons based on size, color, or quality, streamlining the production process.

- Precision Measurement Accurate measurement of button dimensions ensures they meet specified tolerances, improving product uniformity.

Laser Control

- Fast Processing Laser cutting and engraving are faster than traditional mechanical methods, accelerating the production cycle.

- Reduced Downtime Less wear and tear on tools means fewer interruptions for maintenance and tool replacement.

- Precision Measurement Accurate measurement of button dimensions ensures they meet specified tolerances, improving product uniformity.

3. Cost Savings

Machine Vision Systems

- Labor Reduction Automation reduces the need for manual inspection and sorting, lowering labor costs.

- Minimized Waste Early detection of defects prevents defective buttons from progressing through the production line, reducing material waste.

Laser Control

- Lower Tooling Costs Non-contact laser processing eliminates the need for physical tools, reducing tooling costs.

- Energy Efficiency Modern laser systems are energy-efficient, contributing to lower operational costs.

4. Enhanced Flexibility and Customization

Machine Vision Systems

- Adaptability Machine vision systems can be easily reprogrammed to inspect different types of buttons or adapt to new quality standards.

- Scalability The system can be scaled up to handle increased production volumes as needed.

Laser Control

- Custom Designs Laser systems allow for easy customization of button designs and patterns, catering to specific customer requirements.

- Quick Changeovers Switching between different designs or production runs is quick and easy with laser systems, enhancing flexibility.

5. Data Collection and Analysis

Machine Vision Systems

- Real-Time Monitoring Continuous monitoring and data collection enable real-time quality control and immediate corrective actions.

- Process Optimization Data analysis helps identify trends, pinpoint issues, and optimize the production process for better efficiency and quality.

Laser Control

- Process Feedback: Laser systems can provide feedback on processing conditions, allowing for adjustments to maintain optimal performance.

- Traceability: Detailed records of production parameters and outcomes enhance traceability and compliance with industry standards.

6. Safety and Reliability

Machine Vision Systems

- Non-Contact Inspection Machine vision provides a non-contact inspection method, reducing the risk of damage to delicate buttons.

- Reduced Human Exposure Automation reduces human exposure to potentially hazardous environments, enhancing worker safety.

Laser Control

- Precision Control Precise control over the laser parameters ensures safe and reliable operation, minimizing the risk of accidents.

- Automated Safety Features Modern laser systems come with automated safety features to protect operators and equipment